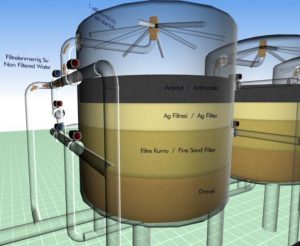

Filtration is a physical, biological or chemical operation that separates solid matter and fluid from a mixture with a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate.Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles (depending on the pore size, filter thickness and biological activity). Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms.

Types

Vacuum filters work by creating pressure at the outlet of the filter media that is higher than the pressure in the outside atmosphere. In other words, vacuum filters create a vacuum. This causes the outside to push itself into the vacuum, where it encounters the filter media.

Pressure filters do their work by applying pressurized fluid or compressed air to force a fluid stream through their filter media. As the stream moves through the filter media, the media catches and removes any suspended debris and separates out unwanted materials.

Membrane filtration is a popular type of filtering system that makes use of a thin sheet to strain liquids.

In-line filters are filters installed along flow lines. Their job is to catch contaminants and prevent system clogging.

Chemical filters dissolve contaminants by pulling them out of the solution as it flows through the filter.

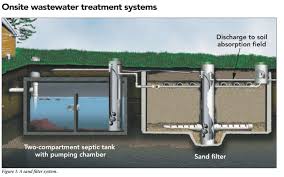

Biological filters can be used to remove organic compounds, but this function is less common.

Two different types of filtration systems use an electrical charge to cleanse air or fluids: electrodialysis systems and electrolysis reversal systems.

Electrodialysis systems (ED) have membranes that allow either negatively charged or positively charged ions to flow through. Note: they do not allow both ion types to flow through.

Electrolysis reversal systems (EDR) work in a similar way. However, EDRs periodically reverse the current in order to generate a fresh flow.

Other less common types of filters are reverse osmosis (RO), ultrafication (UF), and electrodeionization (EDI). Although these are all less common than ED or EDR systems, they are just as efficient and come with their own distinct advantages.

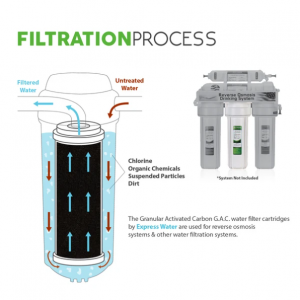

Reverse osmosis systems work by pushing pressurized water through a membrane. They block any impurities from coming along with it.

Ultrafication filters are designed to remove particles and organisms sized between 0.003 and 0.1 micrometers. Examples of organisms this size include viruses and bacteria.

Electrodeionization filters use a combination of electricity, membranes, resin, and ion exchange. To purify water, they deionize it and remove the dissolved ions.

Progression filtration systems are a good choice in industries where solid recovery is a priority. This is because these systems sort contaminations based on its size.

Oil filtration systems are filtration systems designed specifically to filter oil. They are staples of equipment that run on oil, like cars, trucks, manufacturing equipment, and agricultural equipment. Oil filtration systems remove particles from all types of oil, including hydraulic oil and motor oil.

Coalescing filters are another specific filter type designed to meet particular specifications. Coalescing filters catch and remove mists, vapors, and oils from process air streams.

Water filters remove contaminants, microorganisms, and particles from tap water, drinking water and wastewater. In systems that produce ice and water, they can also serve as refrigerator water filters.

Pool filters are a type of water filter designed specifically to clean pool water. These water filters are usually designed as small and removable cartridge filters.

HEPA filters, or High Efficiency Particulate Air filters, are filters designed to remove up to 99.999995% of particles they process. They are important for use in airplane cabin ventilation, industrial vacuum systems, respiration, and more. To be considered HEPA filters, they must be certified.